- NOVUM

- Custom developments

Production support systems

Based on the decades of experience, we develop customized software solutions for production support.

Workplace terminal

- Program upload and download for CNC machine tools

- Displaying production plans and various types of informations

- Reporting production events (failure, need for support, finished workpieces, etc.)

Central server

- Serving out workplace terminals, collecting and storing production data

- Connection with external systems

- Performing tasks related to production events

- Performing periodic and automatic tasks

Office workstations

- Production scheduling tasks

- Monitoring production

- Various types of administrative tasks

- Analysis, evaluation, statistics

Custom postprocessor development

The users of NC/CNC machine tools often face the problem that the major difficulty in modernizing the control is the existance of thousands and thousands of NC programs that need to be rewritten and tested, which is rather expensive. NOVUM has a number of references in solving this problem. Running in batch processing mode, these translator softwares perform this task as well as the syntactic and semantic check of the processed NC programs in a few minutes.

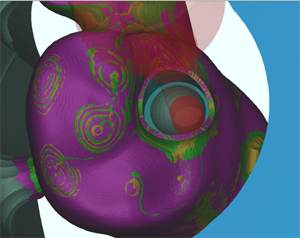

Dental CAM software

The function of this dental application software is the creation of milling programs of dental restorations for Cobra 4 and Cobra 6xe CNC milling machines.

Facilities

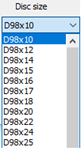

Disc stock

Registration of new discs in a database on the basis of size, material, color and manufacturer.

Projects

Opening new project for a given manufacturing task by selecting a new or used disc from the disk stock.

Importing restorations

Importing restorations in one of the standard CAD formats.

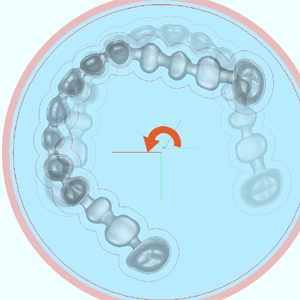

Part orientation

Optimizing the orientation of parts for good machinability.

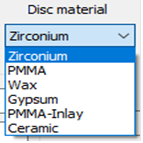

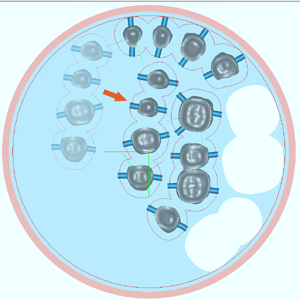

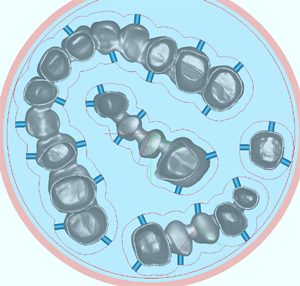

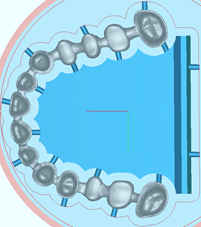

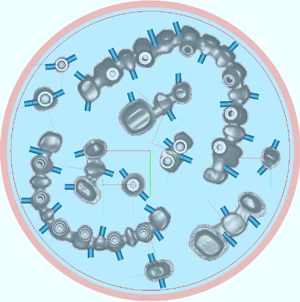

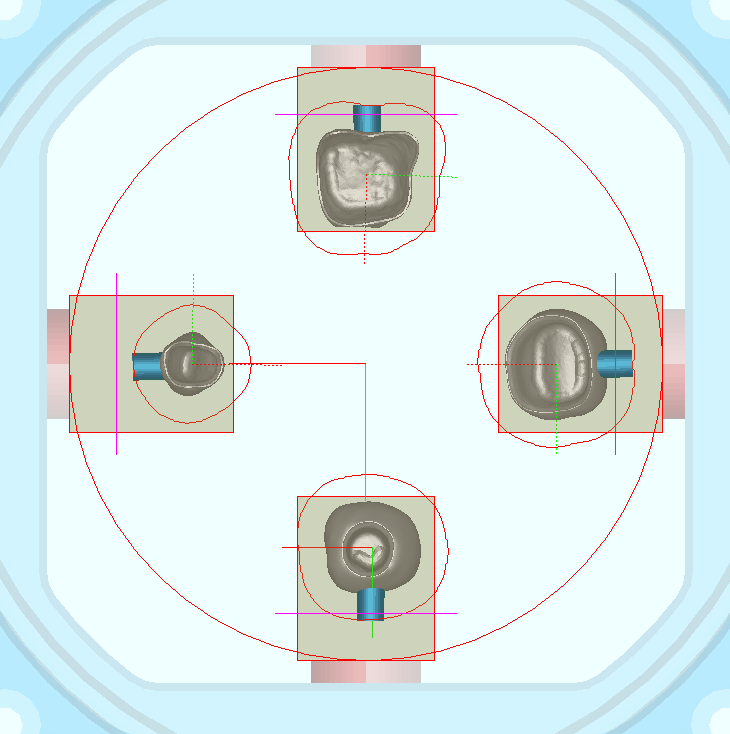

Nesting

Part moving and free orientation possibilities for the optimum nesting of the disc.

Holders

Placing manufactoring holders, some holders can be removed or weakened in the final manufactoring stage.

Stabilizers

Placing stabilizers to avoid sintering deformation.

Set of technologies

Comfortable configuration of manufacturing technologies.

NC program generation

Fully automatic, fast generation of 5 axis milling program for the available tool set with immediate simulation on a point cload.

Click on the picture for CAM software video

BOOL options

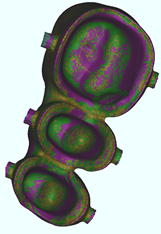

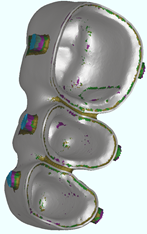

Performing boolean comparison of the imported model with the end result of the simulation of the generated program. Showing excess material. Showing missing material.

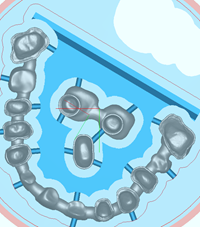

Simulation

Retrospective simulation of the manufacturing programs on a point cloud or on a solid model (see below).

Hole milling

Screw hole milling technology for different tools i.e. square tool.

Glass-ceramic

Wet milling glass-ceramic blocks with smart margin detection and margin technology.

Click on the picture for CAM software video

Manufacturing

Sending the manufacturing program via network to the CNC milling machine.